Feb 22, 2024 | Energy Future, Reliability

This week is Engineers Week, a time dedicated to celebrating all that engineers do to make a difference, while promoting the need for more engineers in society. We’re proud of our hardworking, innovative engineers who help push us toward our goal of becoming the utility of the future.

Francis Frank is one of our engineers making a difference both here at PPL Electric and beyond. As the director of grid modernization, he’s tasked with keeping our grid reliable for years to come.

“I look at the grid today, and I prepare it for the future,” Frank said. “I’m figuring out how solar, electric vehicles, wind and other renewable energy sources will affect the grid.”

As Francis looks toward the future, he’s motivated by his past. He is a proud native of the Caribbean island country of Grenada. From a young age, he took an interest in how energy worked at home.

“I saw how the lack of proper administration of power services, like power distribution, affected the island,” he said. “I was always interested in figuring out why a country with so much sunshine was powered by diesel.”

Francis received an associate degree in Grenada before moving to the United States. His plan was to get a second degree and head home. Over 20 years later, he is still making a difference in the U.S. He joined PPL Electric in September of 2022, and has been working with his 67 team members to advance a safe, reliable and affordable electric future. Francis says that progression would not be possible without his team.

“My team is the valuable resource that enables my success,” he said. “Our engineers and technicians provide the technical solutions to enable the grid modernization projects and processes. The foundation of this team is allowing us to become the utility of the future.”

Although he stayed in America, his roots are still deeply embedded in the communities that make up Grenada. He is the president of his family’s foundation, dedicated to helping provide schoolbooks, fees, uniforms and more to local students.

“I’m blessed,” he said. “I consider myself, first and foremost, an ambassador to Grenada. The foundation is a way to represent my country and help it come together as one nation with one future.”

As an engineer, Francis says he would love to see some of these students be inspired by the island around them and take a similar path, but he says there’s also a need for engineers here in the U.S.

“Engineers are so valuable,” he said. “We need to encourage STEM programs in our education systems, so we can have engineers ready to come up with important solutions in our future. Our value should always be celebrated and encouraged.”

Francis solves problems today that positively impact the years ahead. He’s engineering a clean, affordable energy future, while engineering an educational foundation for children in his native country.

“It’s hard work, but it’s rewarding because I know where I come from and I’m blessed to have this opportunity,” he said. “Somebody ought to do it, and I’m blessed that I’ve been chosen to take it on.”

We are grateful for Francis and the many engineers that help us provide safe, reliable power to over 1.5 million customers.

Jan 3, 2022 | Reliability

When there’s a problem — or a fault — on a power line, it can cause power outages for our customers. But thanks to a game-changing new system, these problems impact fewer customers than ever. The new system, created by our own engineering teams and vendor partners, uses smart devices that interrupt faults remotely. They’re called “vacuum reclosers.”

We place them on power lines to monitor the flow of electricity. When a sensor on a line detects a problem, the nearest recloser automatically cuts power from that point in the line. Instead of every customer on the line losing power, only customers downstream of the recloser device are impacted. Then, our crews work as safely and quickly as possible to restore power to everyone who is out.

In November 2021, we installed the first vacuum recloser on a transmission line and plan to install more of these devices at locations that will provide the most benefit to our customers.

This is just one example of our commitment to innovate and invest in technologies that improve reliability.

Apr 27, 2021 | Customer Service

We’re committed to delivering an effortless customer experience, whether we chat on social media, speak over the phone, or interact with you on our website. We’re also committed to continuous learning and improvement. So, when we received customer feedback regarding accessibility issues with our website, we took action.

Here’s what we learned:

- A legally blind customer made us aware that she was having difficulty using her screen reader to pay her bill online.

- Another customer with red and green colorblindness was having difficulty interpreting certain message banners on our website.

Here’s what we’re doing about it:

- Updating our online bill pay section to better support those who are visually impaired.

- To help overcome the color hurdle, we’re testing and implementing designs that use larger icons, which are more noticeable and legible for users with colorblindness.

Taking it a step further:

- We’ll continue checking-in with customers who have disabilities and design our website with accessibility in mind.

- We’re establishing panels of customers who can provide us guidance and insight on accessibility issues as we’re making routine improvements to the website.

We’re continuously learning from customers who access our website differently, so we can make the web experience inclusive for all.

Apr 20, 2021 | Reliability

We’re using technological innovation and data to reduce costs, improve safety, and keep the lights on for our customers.

This past winter we piloted dynamic line rating (DLR) technology on two of our transmission lines. When integrated successfully into operations, this technology has the potential to delay costly investments.

We’re excited to report that our pilot was successful. Thanks to the accuracy reported by our DLR sensors, we didn’t need to build new lines or upgrade the transmission line to avoid congestion.

The use of DLR sensors on our transmission lines saved millions of dollars that can be invested into preparing for the grid of the future. It also prevents us from having to do construction work.

Our company is one of the first to successfully integrate this technology into operations.

Let’s take a closer look at how it works.

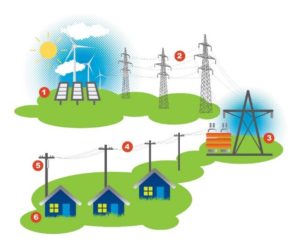

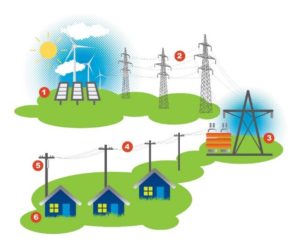

The energy grid moves electricity like the roadway system moves vehicles. The grid has two main components. The transmission system (#2) acts like the highway, moving energy over long distances and across state lines. The distribution system (#4) acts like local roadways, delivering energy directly to homes and businesses.

Like traffic on the highway, the grid becomes congested when the transmission system can no longer deliver the electricity without exceeding certain limits. When this happens, just like roads need to be expanded or added, transmission owners, like us, must upgrade or build new electrical lines.

DLR sensors give real-time information on conditions that affect transmission line performance – like wind speed and line temperature. This information is used to increase the amount of electricity delivered over existing lines and decrease congestion.

Traditionally, static line ratings are taken when the lines are initially built, and the ratings are used indefinitely to make investment decisions. So, even though the environmental factors are continually changing, the rating assumes the most conservative factors are at play. When the grid becomes congested, we may be unable to increase the amount of electricity because the initial static line rating assumes we cannot. This means we must invest in upgrading or adding transmission lines.

“The information we are collecting is helping us better balance strong resiliency while holding down costs,” said Dave Quier, vice president of Transmission and Substation. “Not having to make upgrades to Harwood-Susquehanna saves money, avoids construction work and gives our team more flexibility to invest money where customers will see bigger reliability results.”

This is just another example of how we’re using technology, innovation and data to improve safety, reduce cost, and keep the lights on for you.

Mar 11, 2021 | Reliability

We’re committed to investing in innovative solutions to deliver safe, reliable and affordable energy services to our customers.

Here’s the latest example:

We began piloting Dynamic Line Rating technology to get real-time information on conditions that affect transmission line performance – like wind speed and line temperature. We can use this information to increase the amount of electricity that is delivered over existing lines. This helps us make the most out of our current lines and more precisely identify when lines need to be replaced, which keeps rates affordable for customers.

We recently installed sensors on our Juniata-Cumberland and Harwood-Susquehanna 230kV lines, and we’re actively working on our next installations.

“We are leading the way in our operating region with this technology, and I couldn’t be more excited about how we are using it to improve reliability and decrease cost,” said senior engineer Eric Rosenberger.

Stay tuned for updates on our use of Dynamic Line Rating technology and other innovative investments so we can continue delivering safe, reliable and cost-effective solutions for you.