Jul 14, 2021 | Community Involvement

Keeping the lights on for everyone- in the heat and the cold, when it’s raining or snowing, or even on a blue sky day – is no easy task.

Working in the field requires agility, strength and focus, and commitment to safety above all else.

Earlier this summer, 10 of our lineworkers put their skills to the test in the 9th annual Lineman Rodeo, organized by the National Sisterhood United for Journeyman Linemen (NSUJL), in Hazleton. The two-day event raised money for the families of fallen or injured IBEW (International Brotherhood of Electrical Workers) lineworkers and other electric utility employees.

The PPL crew participated in several events that test their skills against colleagues from utilities, including Speed Climb, Hurtman Rescue, and others. Our linemen and their teams placed in six of the events.

Congratulations to all the competitors!

Jun 24, 2021 | Reliability

Trees are the number one cause of storm-related outages. That’s why we take a proactive approach to keeping lines clear.

Thanks to the combined efforts of our vegetation management program, in 2020, we reduced tree-related outages by 14 percent over the prior year.

Here’s how we do it:

Routine trimming

We trim trees across 33,000 miles of overhead power lines to reduce the risk of outages. We have an established time- and- condition based maintenance program to make sure we’re trimming trees at the right times. We also use data analytics and innovative technology to identify the areas with a higher probability of tree-caused outages.

Don’t attempt to trim or remove trees near our lines on your own. Our qualified line clearance tree trimmers have specialized training to work around our power lines. If you want to remove a tree growing within 10 feet of a power line, call us first.

Goodbye hazard trees

Imagine how difficult and dangerous it is when a large tree brings down power lines in a storm. Assessing the damage, clearing the area for safe repairs, and restoring power to those impacted by a downed line can take hours.

That’s why we proactively remove hazard trees that pose a threat of falling and damaging our lines with permission from the property owner. The removal of these trees in advance of a storm prevents significant damage, removes a safety risk for the public and our employees, and reduces the likelihood of power outages.

In addition to tree trimming, we install animal guards, inspect and maintain our lines and equipment, and continue to improve our smart grid technology to provide you with reliable service all throughout the year.

Jun 24, 2021 | Environment

Each and every year, we conduct tree trimming throughout our service territory to help maintain reliable service and prevent outages. While getting the customers the power they need is certainly our main focus, one of the unique benefits of successful tree trimming is feeding animals like Tatu, the giraffe, at the Lehigh Valley Zoo.

Instead of ending up in a chipper, the smaller branches and tree debris we collect through our vegetation management program are donated to help feed the animals. Tatu, and his other leaf-loving friends at the zoo, can enjoy this especially delicious fare that assists in keeping the animals’ digestive systems running smoothly.

Trees are the number one cause of storm-related power outages, which is why we have an established time-and-condition based maintenance program to make sure we’re trimming trees at the right time.

In 2020 alone, we reduced tree-related outages by 14 percent from the prior year. This work is essential to keeping the lights on and great for curbing Tatu’s appetite.

Apr 20, 2021 | Reliability

We’re using technological innovation and data to reduce costs, improve safety, and keep the lights on for our customers.

This past winter we piloted dynamic line rating (DLR) technology on two of our transmission lines. When integrated successfully into operations, this technology has the potential to delay costly investments.

We’re excited to report that our pilot was successful. Thanks to the accuracy reported by our DLR sensors, we didn’t need to build new lines or upgrade the transmission line to avoid congestion.

The use of DLR sensors on our transmission lines saved millions of dollars that can be invested into preparing for the grid of the future. It also prevents us from having to do construction work.

Our company is one of the first to successfully integrate this technology into operations.

Let’s take a closer look at how it works.

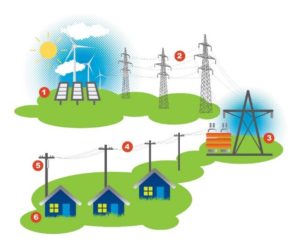

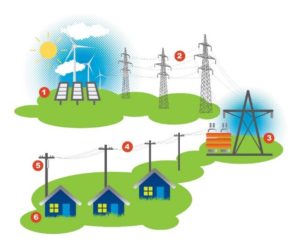

The energy grid moves electricity like the roadway system moves vehicles. The grid has two main components. The transmission system (#2) acts like the highway, moving energy over long distances and across state lines. The distribution system (#4) acts like local roadways, delivering energy directly to homes and businesses.

Like traffic on the highway, the grid becomes congested when the transmission system can no longer deliver the electricity without exceeding certain limits. When this happens, just like roads need to be expanded or added, transmission owners, like us, must upgrade or build new electrical lines.

DLR sensors give real-time information on conditions that affect transmission line performance – like wind speed and line temperature. This information is used to increase the amount of electricity delivered over existing lines and decrease congestion.

Traditionally, static line ratings are taken when the lines are initially built, and the ratings are used indefinitely to make investment decisions. So, even though the environmental factors are continually changing, the rating assumes the most conservative factors are at play. When the grid becomes congested, we may be unable to increase the amount of electricity because the initial static line rating assumes we cannot. This means we must invest in upgrading or adding transmission lines.

“The information we are collecting is helping us better balance strong resiliency while holding down costs,” said Dave Quier, vice president of Transmission and Substation. “Not having to make upgrades to Harwood-Susquehanna saves money, avoids construction work and gives our team more flexibility to invest money where customers will see bigger reliability results.”

This is just another example of how we’re using technology, innovation and data to improve safety, reduce cost, and keep the lights on for you.

Mar 11, 2021 | Reliability

We’re committed to investing in innovative solutions to deliver safe, reliable and affordable energy services to our customers.

Here’s the latest example:

We began piloting Dynamic Line Rating technology to get real-time information on conditions that affect transmission line performance – like wind speed and line temperature. We can use this information to increase the amount of electricity that is delivered over existing lines. This helps us make the most out of our current lines and more precisely identify when lines need to be replaced, which keeps rates affordable for customers.

We recently installed sensors on our Juniata-Cumberland and Harwood-Susquehanna 230kV lines, and we’re actively working on our next installations.

“We are leading the way in our operating region with this technology, and I couldn’t be more excited about how we are using it to improve reliability and decrease cost,” said senior engineer Eric Rosenberger.

Stay tuned for updates on our use of Dynamic Line Rating technology and other innovative investments so we can continue delivering safe, reliable and cost-effective solutions for you.